The Promise of 3D-Printed Earthquake-Proof Homes For Building Resilient Futures

Special to PalmInfocenter.com

Earthquakes pose a significant threat to communities worldwide, prompting the development of innovative construction techniques aimed at mitigating the devastating impact of these seismic events. One such promising advancement is the emergence of 3D-printed earthquake-proof houses, which offer a compelling solution to the challenges of building in earthquake-prone areas.

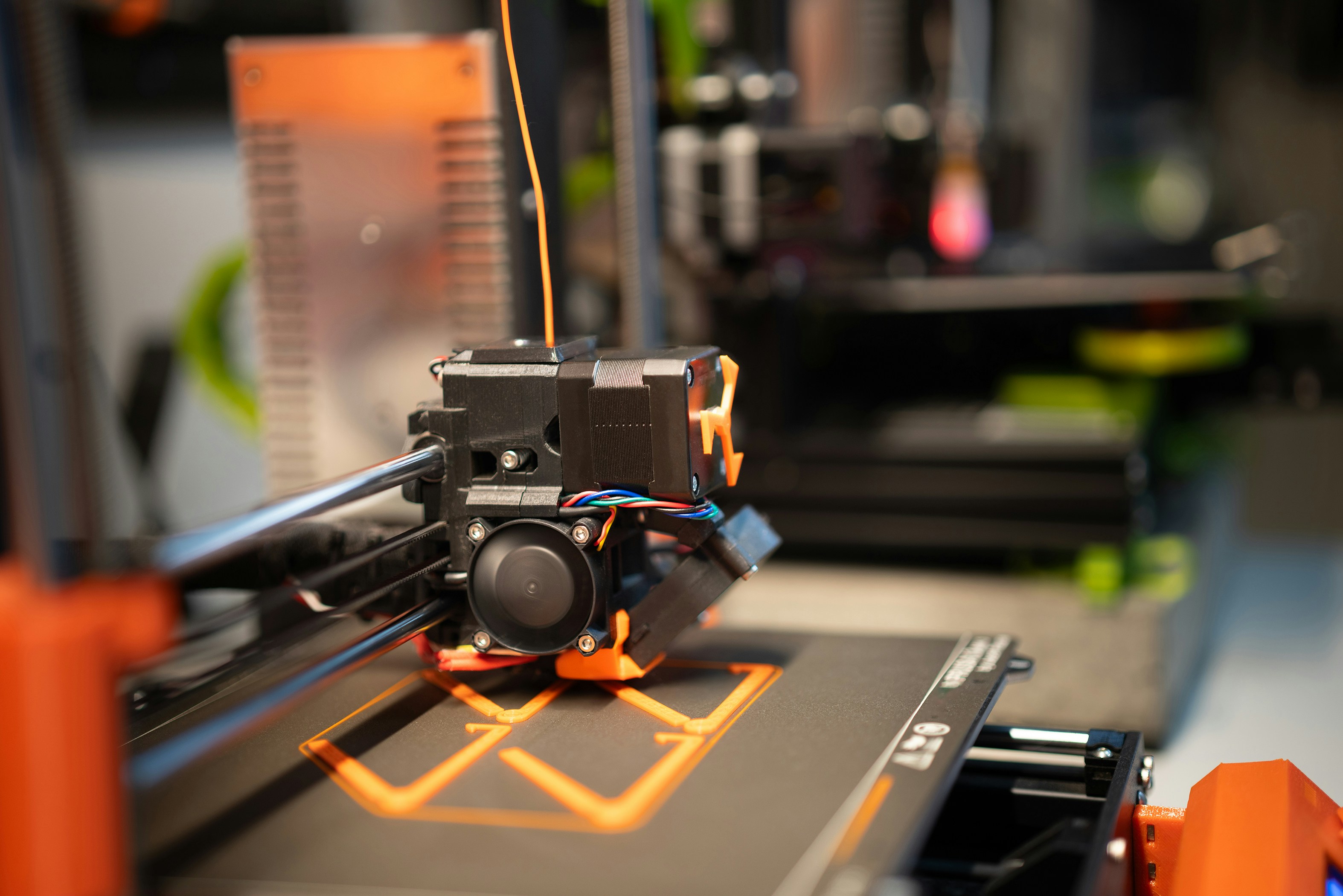

The Potential of 3D Printing in Construction

3D printing, also known as additive manufacturing, has revolutionized various industries by allowing the creation of complex structures with remarkable precision and efficiency. In construction, this technology enables the fabrication of entire buildings layer by layer using specialized machinery. The process not only reduces material waste but also significantly cuts down construction time and costs, making it an attractive option for creating affordable and sustainable housing.

When applied to the construction of an earthquake proof house, 3D printing offers several advantages. The ability to design and produce structures with enhanced strength and flexibility is crucial in regions prone to seismic activity. These houses can be engineered to absorb and dissipate the energy generated by earthquakes, reducing the risk of catastrophic failure. Moreover, the customization capabilities of 3D printing allow for the development of structures tailored to the specific seismic conditions of different regions, further enhancing their resilience.

The Role of Materials in Enhancing Durability

The choice of materials is a key factor in the construction of earthquake-resistant buildings. Traditional construction materials, such as concrete and steel, have been widely used due to their inherent strength. However, the adaptability of 3D printing opens up new possibilities for incorporating innovative materials that can further improve the durability of structures.

For instance, composite materials, which combine the best properties of different substances, can be used to create walls and foundations that are both strong and flexible. Additionally, the precision of 3D printing allows for the incorporation of advanced features, such as shock-absorbing layers and internal reinforcements, which can enhance the overall stability of the building. These materials can be engineered to withstand not only the forces of an earthquake but also other environmental challenges.

Another exciting application of 3D printing technology in sustainable construction is the development of artificial reef design. These reefs, built using eco-friendly materials, serve as protective barriers that reduce coastal erosion and provide habitats for marine life. The same principles of resilience and durability that apply to earthquake-proof housing can also be applied to the design of these reefs, demonstrating the versatility of 3D printing in addressing various environmental challenges.

Challenges and Future Prospects

While the potential of 3D-printed earthquake-proof homes is immense, there are still challenges that need to be addressed. One of the primary obstacles is the initial cost of setting up 3D printing facilities and acquiring the necessary technology. Additionally, regulatory frameworks in many countries have yet to catch up with the rapid advancements in 3D printing, creating a need for updated building codes and standards that can accommodate this new construction method.

Despite these challenges, the good news is that the future of 3D-printed construction is bright. As technology continues to advance and the costs of 3D printing decrease, we can expect to see more widespread adoption of this innovative approach to building.